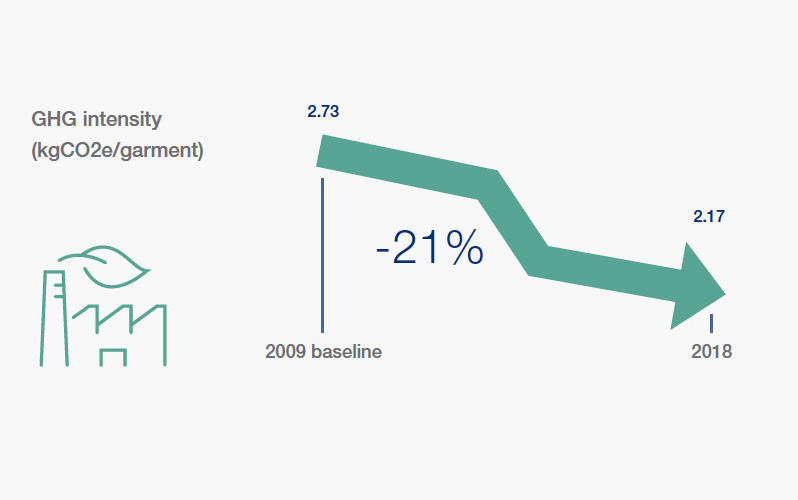

TAL Apparel has adopted the Greenhouse Gas (GHG) Protocol for quantifying and reporting our GHG footprint. In 2009, by using that year as our baseline, we set our first Greenhouse Gas (GHG) target.

ENERGY AND CLIMATE CHANGE

From 2009 to 2018, we reduced our GHG intensity per unit of production by 21%. This translates to the avoidance of 23,450 tonnes of CO2 equivalent GHG emissions from our operations, or about 54,292 barrels of oil.

In 2019, TAL joined the Fashion Industry Charter for Climate Action (FICCA). Signatories to FICCA commit to bold climate action by 2030. TAL set a 45% GHG emissions reduction target by 2030 compared to a 2018 baseline. To ensure our GHG emissions trajectory meets this 45% target, TAL set an 11% GHG Intensity reduction target by 2022 compared to our 2018 baseline.

For more information on our GHG Intensity Reduction efforts, please refer to our latest 2018 Sustainability Report (pages 50 - 52, 59 - 60).

LEED CERTIFIED BUILDINGS

TAL has three buildings LEED certified. These certifications demonstrate our commitment to sustainability as a long-term value proposition. Both of factories in Vietnam are LEED Gold Certified, and our Hong Kong HQ Building is LEED Platinum.

For more information on our LEED certification, please click here.

Water Stewardship

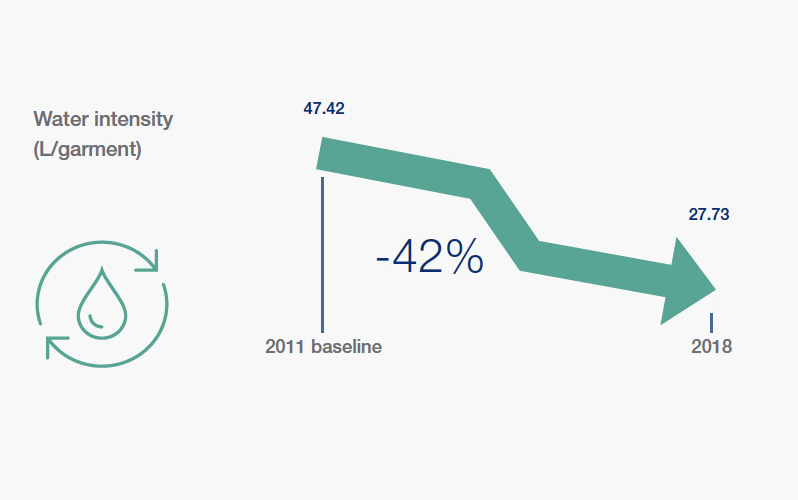

TAL began measuring its water footprint in 2011. Since 2011, TAL has reduced its water intensity by 42%. This is equivalent to the avoided water use of 214 Olympic sized swimming pools. In 2019, TAL set new targets to reduce our water intensity by 35% compared to a 2018 baseline.

For more detailed information on our water stewardship, please refer to our latest 2018 Sustainability Report (pages 53 - 55)

Waste Management

To reduce the amount of waste we send to landfills, TAL Apparel practices waste prevention and recycling.

One of our most exciting sustainability initiatives is creating new garments from the cotton scraps from our cutting tables. To reduce waste in our factories, we are turning the conventional linear product life cycle of a garment into a circular one. This "Closed Loop" initiative seeks to recycle and up-cycle waste wherever possible.

By developing recycled cotton products, we are providing eco-conscious brands, retailers and consumers with exciting new choices.

Wastewater Discharge

TAL is committed to meet local wastewater standards, ZDHC wastewater guidelines as well as the bluesign standard. TAL originally made investments to exclusively use biological treatments in all of our wastewater treatment plants. This is because in chemical treatment the chemicals used often take an additional toll on the environment. However, with increasingly stringent regulations and industry standards we now use some chemical treatment to ensure all wastewater quality parameters are met before discharging from our factories.

We are also continually investing in water recycling technologies. In 2018, we recycled approximately 13% of our total water use. This will improve over the years as one of factories in Thailand invested in Reverse Osmosis technology to recycle our industrial wastewater, and our China factory is boosting its water recycling capacity.